-

AlexanderBetrouwbare leveranciers

AlexanderBetrouwbare leveranciers -

LouisHet was een genoegen om met je te werken.

LouisHet was een genoegen om met je te werken.

Hoogthermische-efficiëntie horizontale boilereconomizer met 1 jaar garantie en serpentinebuisontwerp

Neem contact met me op voor gratis monsters en coupons.

WhatsApp:0086 18588475571

WeChat: 0086 18588475571

skypen: sales10@aixton.com

Als u zich zorgen maakt, bieden we 24-uurs online hulp.

x| Type | Natuurlijke Omloop | Structuur | waterbuis |

|---|---|---|---|

| Druk | Hoge druk | Stoomproductie | Max. 60 t/h |

| Stijl | horizontaal | Brandstof | Koolbrandstoffen |

| Uitvoer | Warm water | Materiaal | Speciale ketel staalplaat |

| Thermische efficiëntie | 92,4%--94,5% | Werkdruk | Hoge druk |

| Gewicht | 1-20 ton | Smelteproces | EF+LF + VD |

| Materiële standaard | ASTM, EN of ISO etc. | UT norm | ASTM A388 of EN10228, enz |

| Proces | Materiaal-> ingot -> warm/cold -rolling-> warmtebehandeling (normaliseren+ temperen) -> | ||

| Markeren | Hoogthermische-efficiëntie boilereconomizer,Economisator voor horizontale ketels,1 jaar garantie serpentinebuiseconomizer |

||

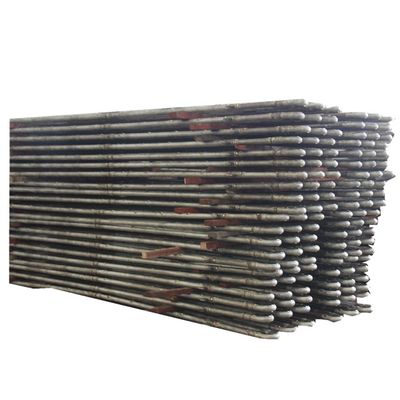

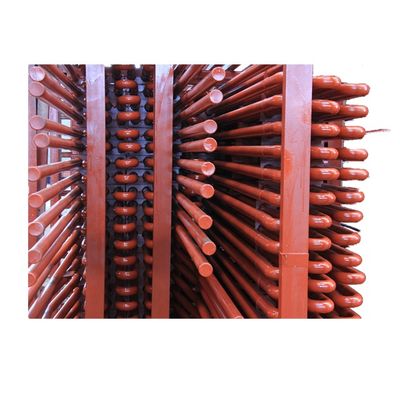

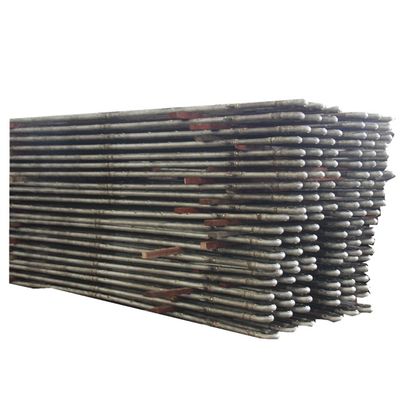

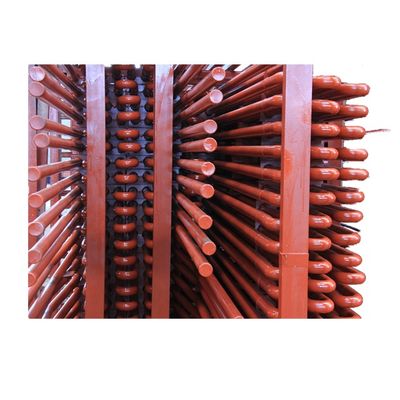

De boiler economizers zijn warmtewisselapparaten met vinnen die vloeistoffen (meestal water) verwarmen tot temperaturen onder hun kookpunt.

- met een vermogen van niet meer dan 10 kW

- Economisatoren met H-vinnen

- spiraalvormige spiraalvormige spiraalvormige spiraalvormige spiraalvormige spiraalvormige spiraalvormige spiraalvormige spiraalvormige spiraalvormige spiraalvormige spiraalvormige spiraalvormige spiraalvormige spiraalvormige spiraalvormige spiraalvormige spiraalvormige spiraalvormige spiraalvormige spiraalvormige spiraalvormige spiraalvormige spiraalvormige spiraalvormige spiraalvormige spiraalvormige spiraalvormige spiraalvormige spiraalvormige spiraalvormige spiraalvormige spiraalvormige spiraalvormige spiraalvormige spiraalvormige spiraalvormige spiraalvormige spiraalvormige spiraalvorige spiraalvorige spiraalvorige spiraalvorige spiraalvorige spiraalvorige spiraalvorige spiraalvorige spiravorige spiraor

De H-fined tube economizer is een hoge-efficiëntie warmtewisselaar bestaande uit H-fined buizen.

- Vergroot warmte-uitwisselingsgebied

- Verminderd aantal benodigde buizen

- Uitgebreide rookgasstroom om de stroomsnelheid en slijtage te verminderen

H-vinnenbuizen kunnen worden vervaardigd als dubbele H-vinnenbuizen voor een verbeterde stijfheid, waardoor ze geschikt zijn voor lange buisrijzen.

De spiraalvinnen-economizer heeft een nieuw ontwerp met spiraalvinnenbuizen die ernstige slijtageproblemen aanpakken en de levensduur verlengen.

| Beschrijving | Koelerspaanders |

|---|---|

| Materiaal | Legstaal, koolstofstaal, SA210C, SA213T22 enz. |

| Materiaalnorm | ASTM, EN of ISO enz. |

| Afmeting | Aanpassing |

| Gewicht | Min: 10 ton Maximum: 1000 ton |

| Smeltproces | EF+LF + VD |

| Proces | Materiaal→Ingot→Hot/Cold-Rolling→Hotbehandeling (Normalisatie + tempering)→Inspectie→Ruwbewerking→UT→Tweede warmtebehandeling→afwerkingsbewerking→Inspectie |

| UT-norm | ASTM A388 of EN10228, enz. |

- Verslag van de slagtest en de sterkteberekening met informatie over de gebruikte materialen

- 100% NDT-rapport (niet-destructieve inspectie) van stalen platen, buizen en elektroden

- Röntgen-, γ- en vloeibare penetratietoetsverslag (sweisnaad) om de kwaliteit van de ketel te waarborgen

- Verslag van de hydraulische test om de standaardwerkdruk en de veiligheid te verifiëren