-

AlexanderBetrouwbare leveranciers

AlexanderBetrouwbare leveranciers -

LouisHet was een genoegen om met je te werken.

LouisHet was een genoegen om met je te werken.

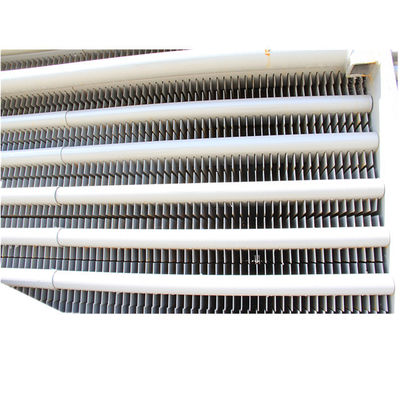

H Fin Tube Economizer met maximaal 20t/h stoomproductie 1 jaar garantie en 5 jaar garantie op kernonderdelen

Neem contact met me op voor gratis monsters en coupons.

WhatsApp:0086 18588475571

WeChat: 0086 18588475571

skypen: sales10@aixton.com

Als u zich zorgen maakt, bieden we 24-uurs online hulp.

x| Type | Natuurlijke Omloop | Structuur | van de soort gebruikt voor de vervaardiging van motorvoertuigen |

|---|---|---|---|

| Druk | Laag/Hoge druk | Stoomproductie | Max. 20 t/h |

| Stijl | Verticaal | Brandstof | Steenkool / Gas / Steenkool / Waterwarmte |

| Uitvoer | Warm water/Stoom | Oppervlaktebehandeling | Geschilderd |

| Materiaal | Legeringsstaal, koolstofstaal, SA210C, SA213T22 | Materiële standaard | ASTM, en of ISO |

| Gewichtsbereik | 10 ton - 1000 ton | Smelteproces | EF+LF + VD |

| Proces | Materiaal-> ingot-> hot/cold-rolling-> warmtebehandeling-> inspectie-> ruwe bewerking | UT norm | ASTM A388 of EN10228 |

| Warmtewisselaarstype | H-finde buiseconomerie | ||

| Markeren | Max 20t/h Stoomproductie H Fin Tube Economizer,1 jaar garantie H Fin Tube Economizer,5 jaar garantie voor kerncomponenten H Fin Tube Economizer |

||

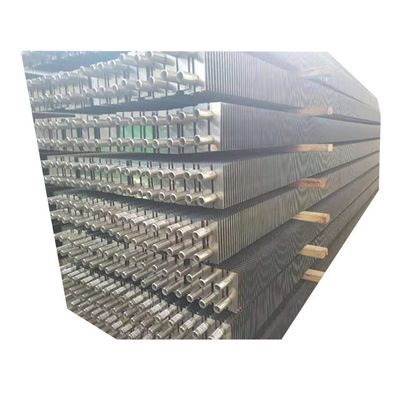

Ketel economizers zijn zeer efficiënte warmtewisselaars met geribbelde buizen, ontworpen om vloeistoffen (meestal water) te verwarmen zonder het kookpunt te bereiken. We produceren drie soorten ketel economizers:

- Economizer met kale buis

- H-geribbelde buis economizer

- Spiraalvormige geribbelde buis economizer

- Vergroot het warmtewisselingsoppervlak terwijl het aantal benodigde buizen wordt verminderd

- Vergroot het rookgasstroomoppervlak om de stroomsnelheid en slijtage te verminderen

- Beschikbaar in dubbele H-geribbelde buisconfiguratie voor verbeterde stijfheid in lange buizenrijen

- Superieur aan ontwerpen met kale buizen in efficiëntie en duurzaamheid

De economizer vermindert de koelingskosten aanzienlijk door de warmteoverdrachtsefficiëntie te optimaliseren, waardoor compressorstops mogelijk zijn met behoud van voldoende koelcapaciteit.

| Beschrijving | Ketel economizer |

|---|---|

| Materiaal | Gelegeerd staal, Koolstofstaal, SA210C, SA213T22 |

| Materiaalspecificatie | ASTM, EN of ISO |

| Afmeting | Aanpasbaar |

| Gewicht | 10-1000 ton |

| Smeltproces | EF+LF+VD |

| Productieproces | Materiaal→Ingot→Warm/Koud walsen→Warmtebehandeling→Inspectie→Ruwe bewerking→UT→2e Warmtebehandeling→Afwerking→Eindinspectie |

| UT-standaard | ASTM A388 of EN10228 |

- Slagproef- en sterkteberekeningsrapporten met materiaalinformatie

- 100% NDT (niet-destructief onderzoek) van staalplaat, buis en elektrode

- Röntgen-, γ-straal- en vloeistofpenetranttestinspectie voor alle lasnaden

- Hydraulische testrapporten om de werkdruk en veiligheidsnormen te verifiëren